Whole Chest Oscillating Expectoration Machine Whole Chest Oscillating Expectoration Machine,Chest Expectoration Machine,Expectoration Machine,Oscillating Expectoration Machine JIANGSU JIANLAIBANG MEDICAL EOUIPMENT CO.,LTD , https://www.jsjlbmed.com

What Exactly is “Food Grade†Stainless Steel?

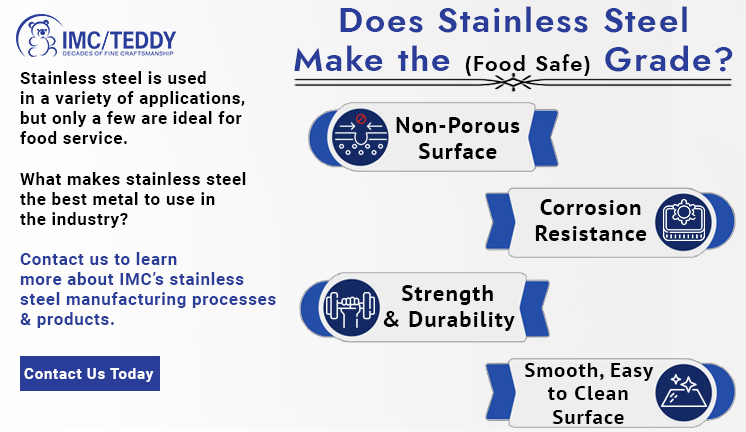

Stainless steel is widely recognized as one of the most versatile metals on Earth. It finds applications in construction, architecture, medicine, and, of course, food service. However, not all stainless steel varieties meet the criteria to be deemed "food grade." Out of the more than 150 grades available, only a select few are considered suitable for use in food-related applications. So, what makes certain types of stainless steel food-safe?

In this article, we’ll explore the four essential qualities that stainless steel must possess to be classified as "food grade." Additionally, we’ll delve into the specific grades that fall under this category. Let's get started.

First and foremost, stainless steel must have a non-porous surface. This quality is crucial because it ensures that the material is highly hygienic and resistant to contamination. Unlike other metals, stainless steel doesn’t allow bacteria or viruses to penetrate its surface, making it ideal for environments where cleanliness is paramount.

Next, corrosion resistance is another critical factor. Rust poses a significant health risk, so stainless steel is engineered with a thin protective oxide layer thanks to chromium. This layer actively prevents rust formation. Additional elements like nickel and manganese further enhance the metal's ability to resist corrosion.

Strength and durability are also key considerations. Stainless steel is robust enough to endure repeated use and is resistant to pitting, chipping, scratching, and distortion. This means it can withstand frequent cleaning cycles without degrading, ensuring it remains safe for long-term use in food service settings.

Finally, a smooth, easy-to-clean surface is essential. Stainless steel is among the simplest materials to maintain. A mild cleaner and a soft cloth are usually sufficient to keep it looking pristine. This ease of maintenance is invaluable in a food service setting where hygiene is non-negotiable.

Now, let’s talk about the specific grades of stainless steel that qualify as "food grade." Surprisingly, only three grades are considered food-safe:

**Type 304:** This is the most cost-effective and commonly used grade in food service. It combines all the necessary attributes to make it food-safe, including excellent corrosion resistance and ease of welding and shaping. Type 304 is versatile and suitable for nearly every food service application.

**Type 316:** Known as marine-grade stainless steel, Type 316 contains a higher nickel and chromium content than Type 304, making it more expensive but also more durable. It excels in large-scale applications like boilers or outdoor kitchens, where additional corrosion resistance is required.

**Type 430:** Unlike Types 304 and 316, Type 430 is magnetic and offers less corrosion and temperature resistance. It works best in mildly acidic environments.

At IMC/Teddy, we take pride in manufacturing all our products in the United States using Type 304 stainless steel. This grade is widely regarded as the most practical choice in the food service industry due to its strength, affordability, durability, and corrosion resistance. To learn more about our mission, feel free to click [here](#).

[](http://bsg-i.nbxc.com/blog/7e1575ce44906d4fb90efa7e10d1ae55.jpg)

*Disclaimer: The views and opinions expressed in this article are those of IMC/Teddy. Our content is intended for informational purposes only. If you wish to feature this post on your website, please contact us directly. Thank you.*

---

**Share this Post:**

Share on **Facebook** | Share on **Twitter** | Share on **LinkedIn** | Share on **Pinterest**